This is not a step by step but a overview of the mod.

It's not even in correct order so

if you feel uncomfortable doing it, then don't !

Want to make your Minelab GP Extreme or GP3000

ground balance easy by just pushing a button?

A simple mod to your handle and only two wires

take the hassle out of ground balancing. No more

reaching down under and trying to find that darn

Fixed/Tracking switch again.

This is the switch I installed from Radio Shack.

It's a push to activate, not a push on, push off type.

You need to solder about 2 foot of zip cord to it

I took some off an old wall transformer as its small,

regular lamp zip cord is too large for this. Maybe

some speaker wire would work well too. You won't

need the nut that came with the switch.

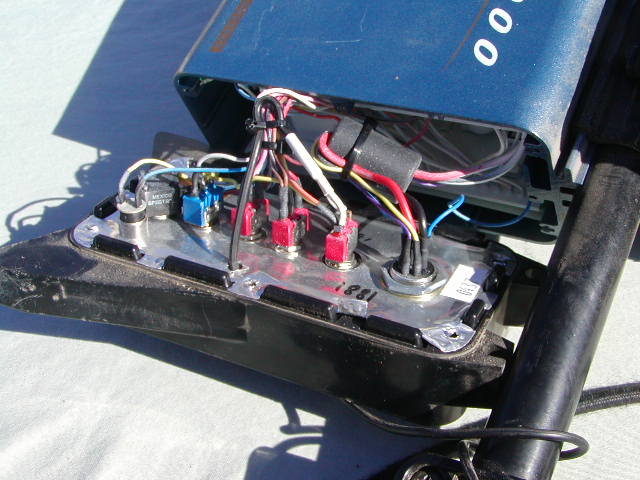

This is the panel you need to remove to get to the

fixed / tracking switch on the right. Remove the six

screws and it will come off. Notice where I drilled

a hole for my switch wire to enter the box near the

Minelab logo. Always look before you drill any hole.

DON'T Drill the hole

with the cover on the Minelab!!!

Your certain to destroy the insides if you do.

Not to mention putting

shavings in there to create havoc!

A close up of the switch (fixed/tracking) we will hook up

to once the cover is off.

If your feeling queasy about doing this mod

STOP

and

FORGET IT !

as its not worth ruining your minelab.

If your an old hand at soldering

and hooking up wires then remove the 6 screws

and lets continue with the mod.

This is what it will look like with the screws removed

and the cover pulled out a little. Be gentle with this

as we don't want to create problems. Here you can see

the switch to the right where I soldered the wires to.

You will find that it has some heat shrink on them like

the other switches in the photo. You will have to trim

off a small bit to get to the switch so you can solder

the wires to it. An exacto knife or razor makes it easy.

Make sure to use a couple zip ties or tie wraps to

provide stress relief to the wire so it won't pull off

putting the cover back on. Don't have zip ties then

use string and tie it in a couple places to the other

wire bundles.

Here is a close up of the switch, even though it has

3 lugs only two have wires on them. These two are

the ones we want to solder to. If you prepare the

wire as I suggest in the next photos, its easy. Just

lay the new wire against the lug and apply heat with

soldering iron and its done. If you haven't soldered

before

STOP NOW.

Get someone that knows how to help!

The ends of the wire are simply laid on the lugs and

heat applied and it should melt in place. That's after

you install it in the handle and route it of course.

I used some large zip cord in this photo to show how

its prepared as its easier to see. Strip about 1/2 inch

off the rubber insulation off the ends and pre tint them

with solder as shown above. Both will be silver colored

with solder when this is done.

Then trim them down to about 1/8 inch of pretined

wire as shown above this will make it easy to solder

to the lugs. Remember this is large zip cord for

illustrations only.

Here is the handle you need to drill a hole in for the

button. I rolled the foam grip downward to get it out

of the way. Predrill a small 1/8 inch hole to get it going

then work larger to get the final size you want for a

snug switch fit. Take it easy doing this as the handle

is very fragile. If you do screw up and break it

Chris Gholson at Arizona Outback

has more of them in stock for about $20.00

I put a drop of glue under it to hold it but

feel it wasn't needed as it fit very snug. You will be

drilling through two layers for the long switch to fit

through. You'll see what I mean if you look at your

handle. A dremel tool may make this easy if you get

your hole off center a little. I even used a file to get

my hole perfectly centered since the Gold Gal had

my dremel tool at her lapidary class.

This is a look at the two layers one at top of handle

and one about 1/2 inch down in the handle moulding.

Then I pulled the wire out and glued it down the ribbed

area to the side. Remember all this needs to be done

before you open the box to drill that hole and solder the

ends of the wires to the switch.

To use this feature you need to leave

your Tracking/Fixed switch in Fixed all the time.

It sure makes ground balancing easy to do.

You can simply do it while detecting and never

skip a beat.

It's Great!